Automated liquid handling applications in industry

Whether it be in quality control, manufacturing, health and safety, there are many disciplines within industry that have benefited from HTZ’s precision liquid handling expertise.

Contact us to find out more

Trace Metal Analysis

Metal Ore Evaluations

Trace Metal quantification is performed by a number of specialised analytical laboratories in order to determine or verify the metal content of various types of samples. Whilst the final quantification is usually perfomed by ICP, AAS or MS the samples often require accurate dilutions preparing before the samples are analysed.

Click here for more information

Metal Wear Analysis

When complex mechanisms, such as internal combustion engines or vehicle gearboxes are used, tiny fragments of metal are worn away and end up in the lubrication oil. Analysing the metal content of the oils provides an indication of which components are wearing the fastest and can be used as an aid to predicting when servicing is required.

Difficulties in processing oil samples

One of the main functions of an oil is of course to cling to a surface to achieve its lubrication role. This feature makes the total removal of that oil from tubing, as used in conventional diluters and dispensers, a difficult task and can limit the accuracy that can be achieved. Furthermore, the wide range of viscosity’s associated with fuel oils through to heavy gearbox oils adds to the problem of total sample removal especially when dilution ratios as low as 10:1 are required. When “used oils” are involved, contaminants compound the problem further. All these problems are overcome or minimised with HTZ’s dedicated oil processing Workstation.

Probe tip

A tapered tip, similar to a conventional disposable tip used on a hand pipettor, is used to retain the entire sample volume. This tip is mounted on a special nozzle that directs the solvent along the surface of the tip rather than through the core of the liquid in the tip. A small proportion of the intended total volume of solvent is used to displace most of the oil sample. Air is then bubbled into the tip through the remaining solvent and oil which then aides the transfer of the remaining oil into the solvent. A little more of the intended total solvent is then used to displace this and the process repeated several more times until total recovery has taken place. A common requirement is to dilute a 0.5ml sample with a total of 4.5ml solvent. The end result is an accurate dilution with minimal wastage of solvent. A satisfactory level of carryover can usually be achieved without a tip change.

Optical Liquid Level Detection

The liquid detection systems, used on many XY Sample Processors, rely on the conductivity characteristics of the sample, but this method of liquid detection is not possible with the majority of oils. The Beeline, therefore, is equipped with an optical device that functions by reflectance from the surface of the liquid, whether this is a clean light oil or a heavily contaminated viscose sample. This allows precise control of the depth to which the sampling tip penetrates the surface of each sample, irrespective of the level to which the container has been filled, to minimise carry over on the external surface of the tip.

Throughput

Beelines equipped with the above special features have been routinely and heavily used over periods of many years for the reliable, consistent and precise dilution of a wide range of oils. So that one system can cope with a whole variety of samples in a single batch, the operating rate has been set to achieve optimum performance without operator intervention. When allowing for this wide range of sample characteristics, the Beeline dilutes samples at the rate of approximately 60 per hour. Alternative operating programmes are available where a higher throughput rate is achieved with a slightly increased risk of carry over when the most viscous oils are encountered.

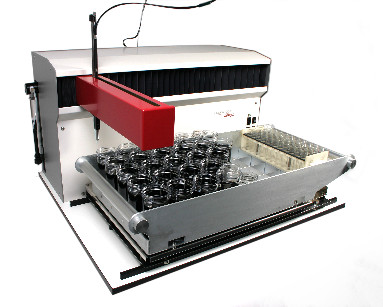

Beeline 300 FD

The Beeline 300 FD is an associated instrument designed as on-line sample feed unit, which operates at the optimum rate of an AAS or ICP. The Beeline 300 FD is equipped with a paddle stirrer so samples that have been prepared many hours before being analysed, are thoroughly mixed immediately prior to aspiration by the AAS or ICP. Once again, the Beeline can be programmed to respond to the requirements of the measuring instrument providing samples, blanks or a range of standards, whenever required, for the optimum performance of the complete system.