SX Racks & Layouts

Precision range of automation friendly racks and custom rack design service

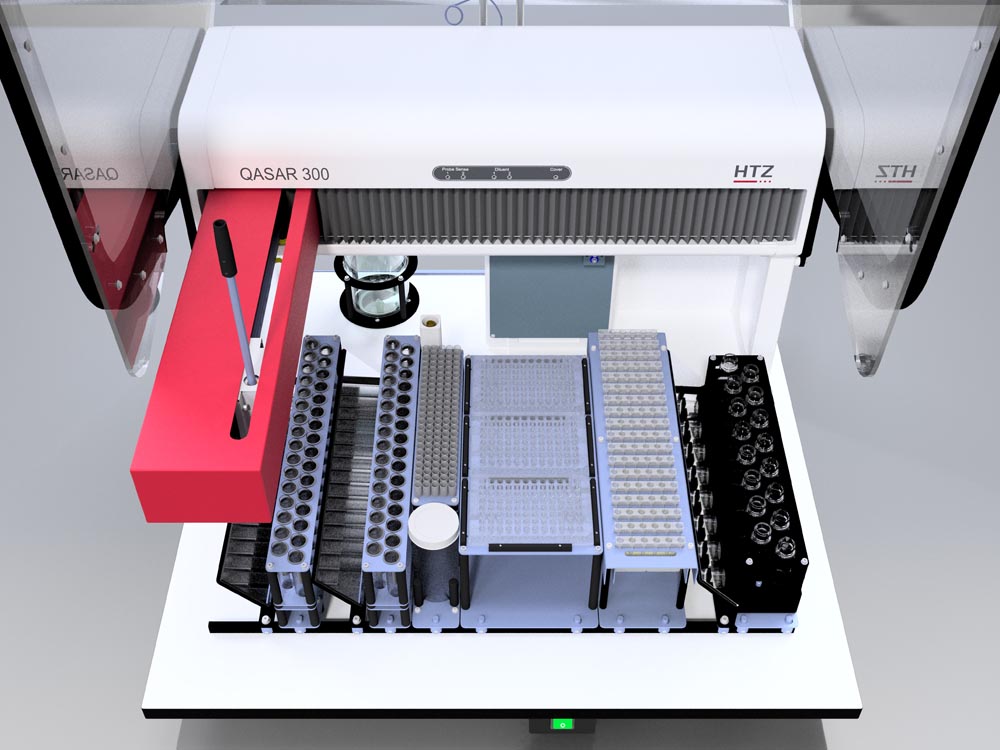

Flexible Deck Layout

The “Deck” of the instrument is the part of the instrument on which all the racks and containers are mounted.

The SX deck is is made from a chemically inert, high-pressure laminate casting very similar to that used for laboratory benchware and is, effectively, a blank canvas onto which you can place whatever racks, accessories and any other items required by the procedure to be automated.

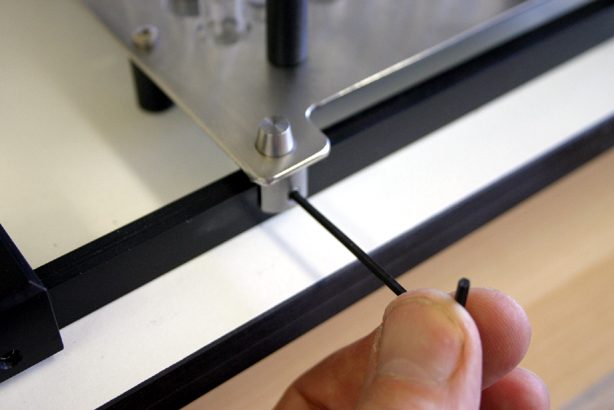

Rack Location System

The basic rack location system comprises a narrow locating “rail” fixed to the deck along the length of the instrument at the back and front. Special adjustable locating “pegs” are fixed on these rails and racks are located on top of these.

Where existing lab racks need to be used, customised adaptor plates are provided which also locate on these pegs. This simple system allows all racks to be located, reproducibly, anywhere on the deck and keeps the deck itself easy to clean. The racks remain easily removable for loading convenience or for cold storage purposes.

For other items, such as the Slide-In-Rack barcode reading module, or accessories such as the microplate incubators, one or more fixing points are provided on the deck itself. The black rack locating rail and rack locators are visible at the front of the Deck illustrating how the racks are located.

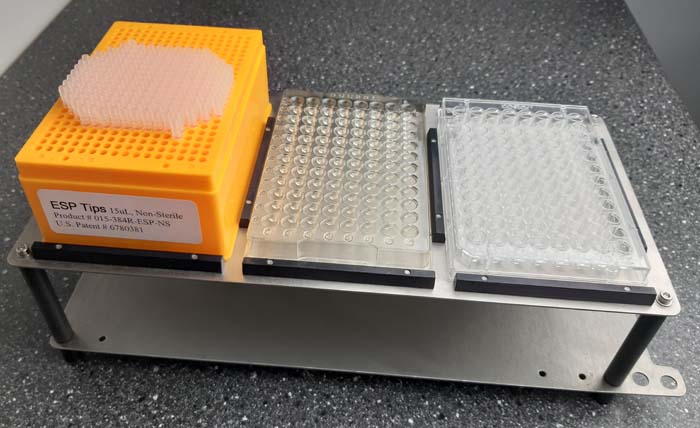

Customised rack options

Whilst HTZ has a comprehensive range of racks available, it is sometimes beneficial to provide custom racks to make the most of the available deck. Most of our racks are made from stainless steel and metal pillars except for some of the very largest racks where heavy gauge aluminium is used to save weight. The base of the racks incorporates at least two locating holes to engage with the rack locator pegs described above.

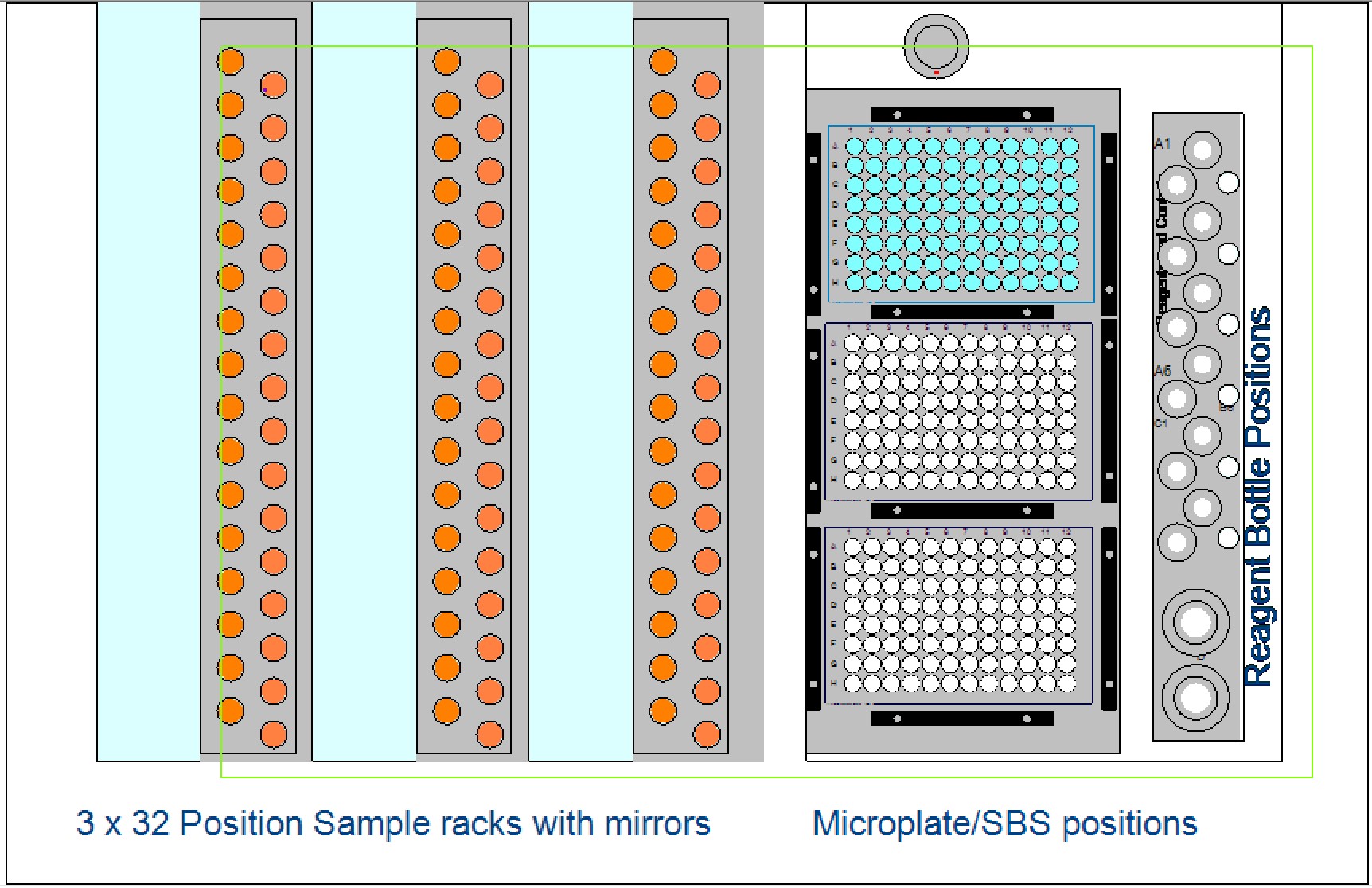

Layouts

A “Layout” refers to the combination of racks and other devices which sit on the deck and which need to be processed by the pipetting probes. With bench space being at a premium, it’s important to optimise the deck to suit individual laboratory requirements. Prior to purchase, we assess the full requirements of your application and will design a Layout to let you know what is possible using standard HTZ or user racks or a combination of both. Sometimes, we may recommend a custom rack if significant gains in capacity or convenience can be achieved. For example, in some situations, customised racks can help avoid an unnecessary transfer of tubes from one rack to another or even the decanting of liquids from one bottle to another.

A key factor affecting the Layout and the capacity of either system will be whether samples and target consumables such as microplates or microplate strips will be barcoded. If they are, then there is a choice of barcode reading technologies available to choose from. See below for further details.

For many labs, a single Layout is sufficient to accommodate all the work that will ever be perfomed by the machine. However, in some cases, it may be more convenient or necessary to have multiple Layouts. For example, one application may require samples to be pipetted into the maximum possible number of microplates that can be fitted on the deck and another may require that samples are pipetted and diluted into a set of 5ml tubes. It is therefore desirable to be able to easily swap between the two different Layouts which, given that most or all of the racks are readily removable, is easily achieved.

Associated with the different physical Layout is a software definition of the Layout. This “describes” to the machine exactly where the racks are located on the Deck in terms of X, Y and Z coordinates. The calibration of these Layouts is achieved simply using a hand-held Joystick or GamePad which drives the probe to one or more key reference cooordinates on the Deck. Adjustments are made, if necessary, and the coordinates confimed using a “Fire” button which records the current position precisely in the Layout definition. It should be emphasised that once defined, these only need adjusting if there is a change to the racks or consumables used by the machine.

There is no limit to the number of Layouts that can be created and it is easy to create new Layouts using HTZ’s CCX3 Applications Software.