LIQUID HANDLING MODULES

A number of options and configurations are optimised for a variety of liquid handling tasks

Introduction

At the heart of nearly all of HTZ instruments is a liquid handling module of one type or another. The function of all of these modules is to pump liquid whether it be a sample pipetting or a simple filling task. Different types of pump are available, each with pros and cons, so the choice is dependent on the application. Here we provide some background to each of the types and their respective merits.

Syringe Drives

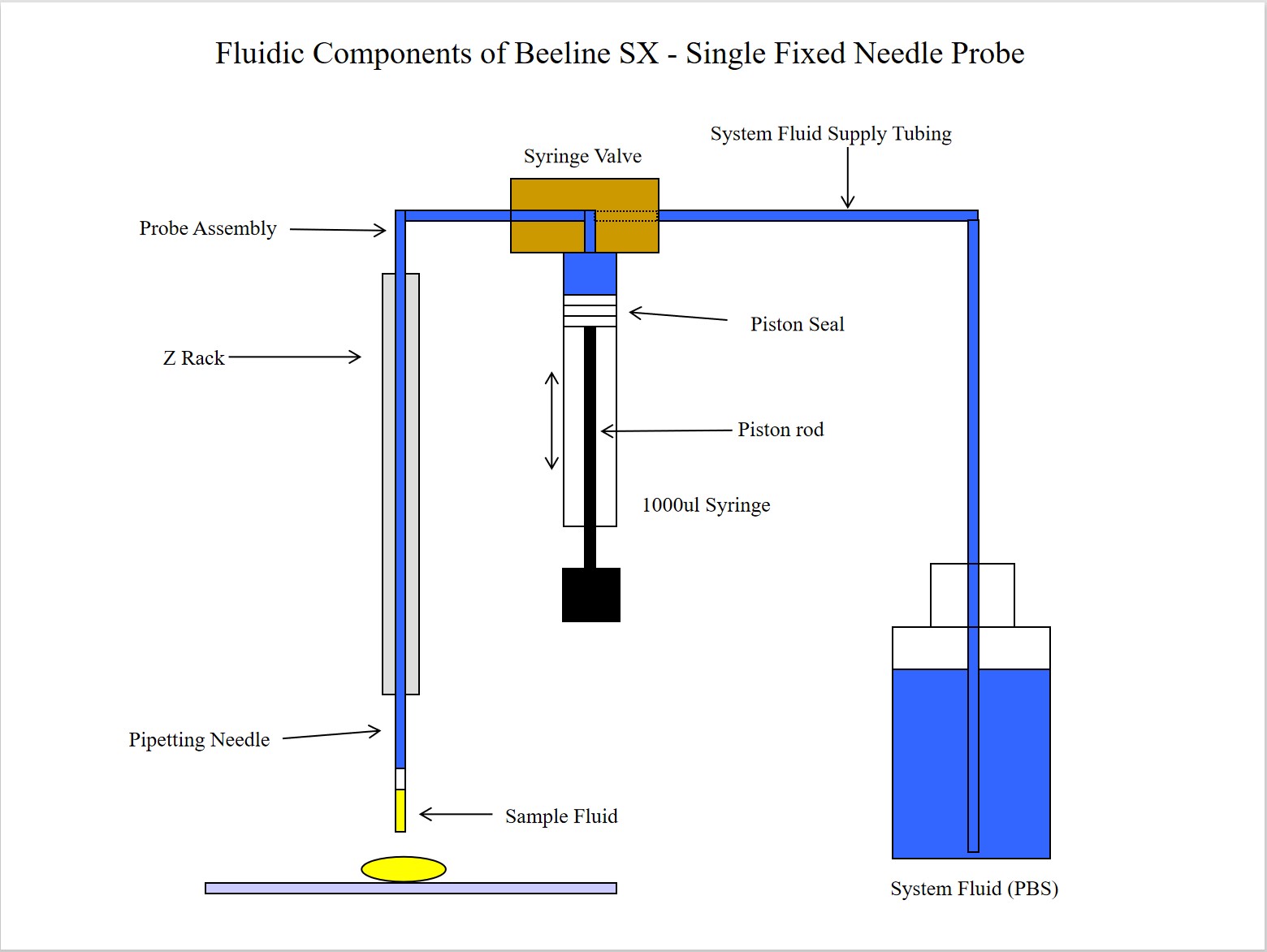

Arguably the most flexible type of pump for many applications is the syringe pump which comprises three main elements namely the Syringe Drive, the Syringe itself and a Valve. The pump is itself is connected to a Sampling Probe, either Fixed (fluid filled) or Disposable Tip (air displacement) and it is this element which is moved around the deck to access samples, reagents and target plates etc. much in the same way as you would with a manual pipette, only faster – in most applications!

Fluidic components of a syringe drive based pipetting system

When pipetting with fixed needles, the entire fluid path is filled with liquid. This is referred to as the System Fluid and may be distilled water or a buffer solution which can be used for the preparation of dilutions. The System Fluid, usually supplied to the syringe from an external reservoir, provides a rigid hydraulic connection between the syringe and the probe needle enabling precise pipetting to be performed despite the distance between the two elements. The System Fluid is also used for the washing of the internal and external surfaces of the probe needle inbetween samples and reagents to avoid cross contamination.

SX Syringe Drive

The Beeline SX range incorporate one or more high-resolution syringe pumps with 20,000 steps on a 60mm stroke so, when fitted with a 1000µl syringe, provides a resolution of 20 steps per µl , e.g. eg one step movement of the motor equates to a volume of 0.05µl . The syringe drives are designed and manufactured by HTZ and use “ballscrews” for maximum possible life expectancy and to provide the excellent accuracy and precision over a long life time.

The ballscrew is the mechanical component which connects the motor to the syringe itself and translates the rotational motion of the motor into the linear movement of the syringe piston and therefore has a critical role to play in maintaining accuracy and reproducibility of the syringe. With minimal routine maintenance, these devices can easily operate for over 20 years of continuous use and longer with typical laboratory duty cycles.

The stepper motor itself provides the motive force to drive the syringe piston up and down and the HTZ syringe pump performs a full 60mm stroke in under 0.5 seconds ensuring that smaller syringes can be refilled faster than with most other units available on the market. This ability provides the Beeline SX with a wide dynamic range and the ability to wash pipetting probes (fixed needles) quickly and, in most cases, without resorting to an auxilliary pump to wash probe needles and reduce sample carryover. However, in some applications where the concentration range of the analyte can be very high, e.g. with tumour markers such as HCG, it can be useful to augment the syringe wash with an additional pump to speed up processing. This approach can reduce carryover to less than 1 in 500,000.

Syringes and valves

Although the Beeline SXs are most commonly fitted with a 1000µl syringe, a range of sizes is available (100µl up to 25mls) to cater for different applications. The barrels are all manufactured from precision borosilicate glass and the pistons seals from a special polymer which provides a long service life. For aggressive chemicals such as strong acids and or with certain organic solvents, PTFE piston seals are also available.

The syringe is closely coupled to either a motorised or solenoid valve to control the direction of flow. For many applications, a solenoid valve offers the best performance and life expectancy and provides reliable operation only requiring occasional replacement during preventative service visits. However, a motorised valve offers the lowest volume change on actuation providing better performance in some applications.

Peristaltic pumps

For applications requiring sterile liquid dispensing or for simple filling tasks, a peristaltic pump version of the SX platform is available. The Periflex 500 SX represents the latest and fastest of these and incorporates two peristaltic pumps. The peristaltic pump offers the highest throughput filling as, unlike a syringe, there is no need for it to refill between dispenses.

The main advantage of a peristaltic pump is that the entire fluid path i.e the tubing itself, is removable for easy replacement or sterilisation as appropriate. Furthermore, it is ideal for dispensing solutions containing paticulates that would otherwise reduce the life expectancy of valves and syringes.

SX Disposable Syringe and Valve

Alternatively, it is now possible to fit the SX with standard medical grade disposable syringes. These are ideal for filling jobs requiring complete sterility, minimal calibration and where the complete fluid path needs to be disposed of when completed. In some applications, disposable syringes offer greater accuracy than peristaltic pumps. We can advise which will be the most appropriate for your application.